OUR VISION

Soft Matter more green

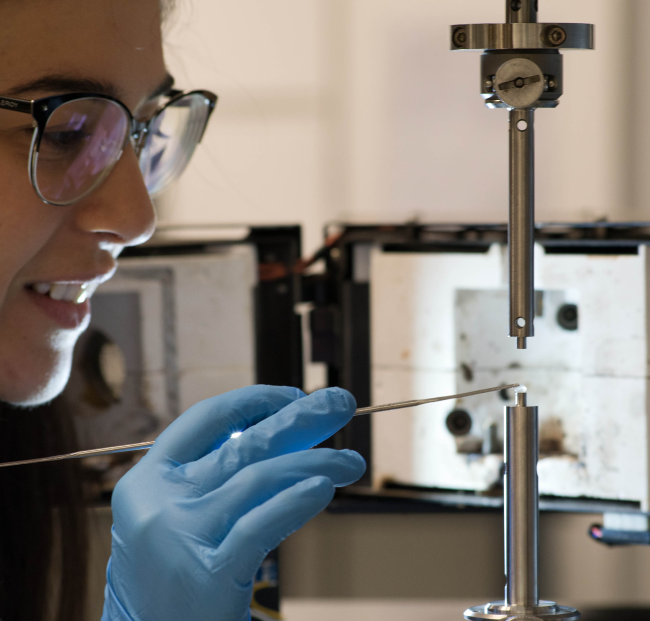

Most of our everyday materials are made out of synthetic compounds that are known to have a negative environmental impact and therefore need to be replaced. Soft Matter sciences are ideally placed to address these issues. We aim with this EU-funded FORGreenSoft project to explore new routes to replace some of these ingredients. The focus is on bio-sourced raw materials obtained through eco-friendly processes. We will achieve this through a multilevel transfer of knowledge and research collaboration between FORTH and European centers of excellence at the University of Vienna in Austria and at the Max-Planck Institute in Germany.

NEWS & EVENTS

Summer School on Computational Methods

September 25th - 27th 2025

FORTH,

Heraklion, Crete, Greece

PARTNERS

PUBLICATIONS

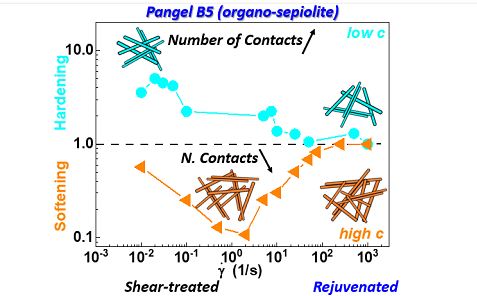

Tuning the mechanical properties of organophilic clay dispersions: particle composition and preshear history effects

Nikolaos A. Burger, Benoit Loppinet, Andrew Clarke and George Petekidis

ABSTRACT:

Clay minerals are abundant natural materials used widely in coatings, construction materials, ceramics, as well as being a component of drilling fluids. Here, we present the effect of steady and oscillatory preshear on organophilic modified clay gels in synthetic oil. Both platelet and needle-like particles are used as viscosifiers in drilling fluid formulations. For both particles the plateau modulus exhibits a similar concentration dependence, , whereas the yield strain is for the platelets and for the needles. Mixtures of the two follow an intermediate behavior: at low concentrations their elasticity and yield strain follows that of needle particles while at higher concentrations it exhibits a weaker power law dependence. Furthermore, upon varying the preshear history, the gel viscoelastic properties can be significantly tuned. At lower (higher) clay concentrations, preshear at specific oscillatory strain amplitudes or steady shear rates, may induce a hardening (softening) of the dispersions and, at all concentrations, a lowering of the shear strain. Hence, in needle dispersions preshear resulted in changes in the volume fraction dependence of the elastic modulus from to and of the yield strain from to . However, small angle X-ray scattering showed not much structural changes, within the q-range covered. Our findings indicate ways to design colloidal organoclay dispersions with a mechanical response that can be tuned at will.